Additives for pigment concentrates

Whenever coatings for buildings, industry or vehicles need to be colored, pigment concentrates are the most flexible way to fulfil all needs. Our large portfolio of additives ensures an efficient dispersing process to reach most stable pigment concentrates with highest color strength.

Benefit from our customized solutions for pigment concentrates

Pigment concentrates must be easy to handle, stable in storage and compatible with many coating formulations. With the help of our additives, you can produce pigment concentrates for intensive and long-lasting colors. Our broad portfolio offers the flexibility you need and the right solution for different technologies and applications.

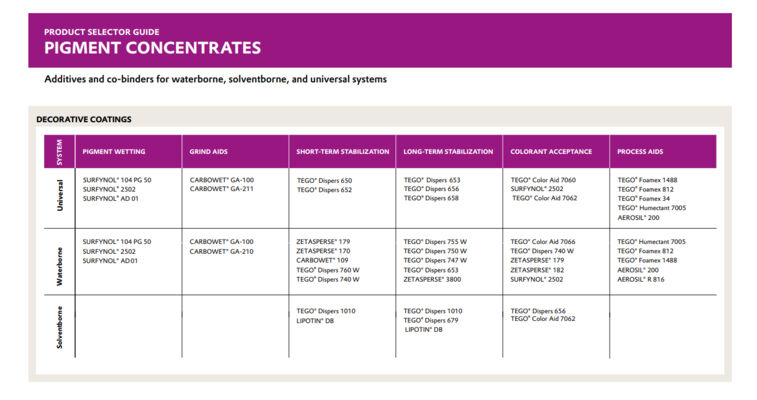

Detailed product recommendations for pigment concentrates

Product selector guide pigment concentrates

Download our condensed product recommendations for pigment concentrates.

Though there are many possible routes to the finished pigment concentrate formulation, Evonik’s high-throughput equipment (HTE) helps you achieve your goal more efficiently. Our HTE is a fully automated system for testing and developing coating additives. It can be used flexibly for a wide range of binders, solvents, additives, fillers, and pigments, and significantly shortens time-to-market through automated testing.

When developing your pigment concentrates, you can rely on our many years of expertise and detailed market knowledge. Along with the support of our experts, customers can access our formulation network COATINO® and the learning platform, COATINO® Campus. There, you can learn everything you need to know about pigments in general, the individual production stages of pigment concentrates, and our corresponding solutions.

- Flexible: Broad portfolio for different technologies

- Efficient: shorten time to market with HTE

- Experienced: Global availability of technical experts

- Digital: COATINO® formulation network and COATINO® Campus learning platform

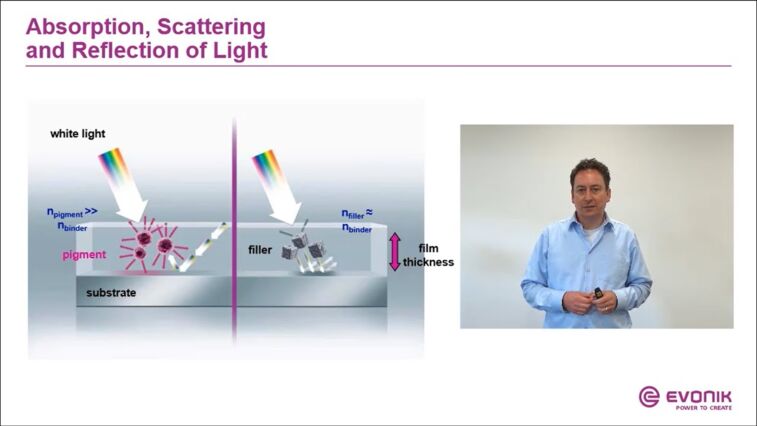

Pigments are the component that give intense color and underline an eye-catching design. As pigments are solid and need to be stabilized in the liquid coating, the challenge in formulation is to wet, grind and stabilize the solid particles to ensure easy handling and outstanding performance. One flexible way to make pigments usable for the coating manufacturer is to transfer them into a liquid and easy-to-handle pigment concentrate.

Another challenge is that modern pigment concentrates should be suitable and compatible with all binder technologies the coating manufacturer might have in his portfolio. Sometimes, they even have to be suitable for waterborne paints and solventborne alkyd lacquers.

To meet demands for color intensity and compatibility in different systems, manufacturers depend on suitable additives for their pigment concentrates in order to improve the wetting, grinding and stabilization of the pigment. The outcome is an efficient liquid colorant that is easy to handle.

Our pigment concentrate additives enable fast wetting of pigment particles to save energy, and their long-storage stability reduces waste.

The TEGO® Dispers 65x series consist of wetting and dispersing additives for universal colorants. Their future proof technology assures that the universal colorants reduce complexity without the need for hazard labeling and are free of volatile organic compounds (VOCs). TEGO® Dispers 658, for example, is even readily biodegradable.

We continuously develop innovative additives for pigment concentrates – both on our own and in collaboration with customers. In doing so, we focus particularly on developing additives that can be used for different coating systems, and work with organic and inorganic pigments, and carbon blacks. We also keep an eye on current trends in the various markets as we continue to develop more effective and sustainable products.

Regulations for end products and Ecolabels limit the choice of additives for pigment concentrates. Our Regulatory Product Finder helps customers choose the right additives according to their specific regulatory requirements. In addition, our Regulatory Team constantly monitors regulatory developments, so customers can be reassured our products stay compliant.

Our additive portfolio for pigment concentrates contains: wetting and dispersing additives, defoamers and deaerators for all kinds of pigment concentrates, humectants for waterborne and universal pigment concentrates, and compatibilizers to improve the color acceptance of waterborne and solventborne coating formulations.

We offer additives specifically designed for various coating systems, as well as products that can be used universally for different technologies. Our wetting and dispersing agent toolbox e.g., facilitates the formulation of universal colorants. It provides benefits on color strength, viscosity reduction, and compatibility with various binders. In addition, TEGO® Dispers 658 – is a sustainable product especially developed for organic pigments and carbon blacks.

Get advice from our experts or through the Pigment Concentrate Finder, which allows customers to filter products by dispersing additives, pigments, binders and properties.

TEGO® ColorAid

New compatibilizers improve the use of universal pigment concentrates in alkyd resin coatings.

TEGO® Dispers 628 & TEGO® Dispers 655

Get ready for TiO2 reformulations and find out more about our additives for high-quality solventborne direct grinds.

An Efficient Approach to Dispersing Pigments

Download our white paper here. ... MORE