Additives for heat-resistant coatings

Heat-resistant coatings are commonly used in a variety of industrial applications. Their main task is to protect the substrate and/or to provide a decorative surface at high temperatures (> 180 °Celsius for an extended period of time). Along with industrial applications such as mufflers and fire places, there is also a need for these coatings on cook- & bake-ware, which can be achieved by the use of silicone-containing resins.

WATERBORNE

A waterborne coating is an environmentally friendly surface treatment that uses water as a solvent to disperse the resin used to make the coating or paint. Water comprises a minimum of 80% of the solvent used. Its aim is to make the coating or paint an easy-to-apply, eco-friendly product. Waterborne coatings are widely used due to their low VOC (volatile organic compounds) content.

SOLVENTBORNE

Solventborne coatings are surface treatments that contain VOCs. Advances in waterborne coatings are making them an increasingly attractive option as a method of protecting material surfaces even in harsh conditions. Solventborne coatings can be differentiated by their VOC content, which can range from medium solids (approx. 50% VOC) up to ultra high solids (less than 10% VOC).

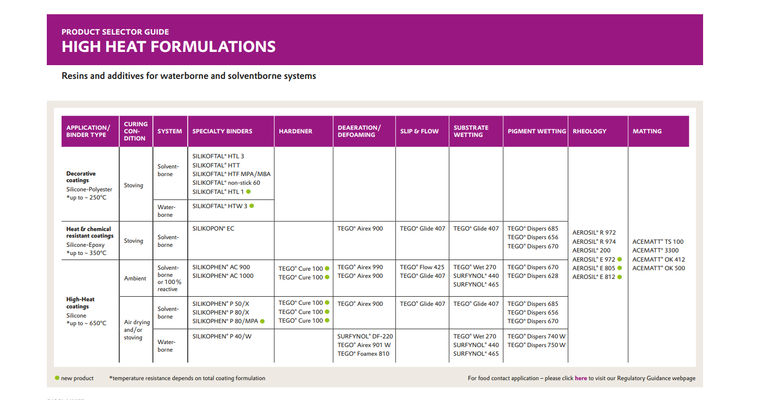

Detailed product recommendations for high heat coating formulations

Product selector guide high heat coating formulations

Download our condensed product recommendations for high heat coating formulations.